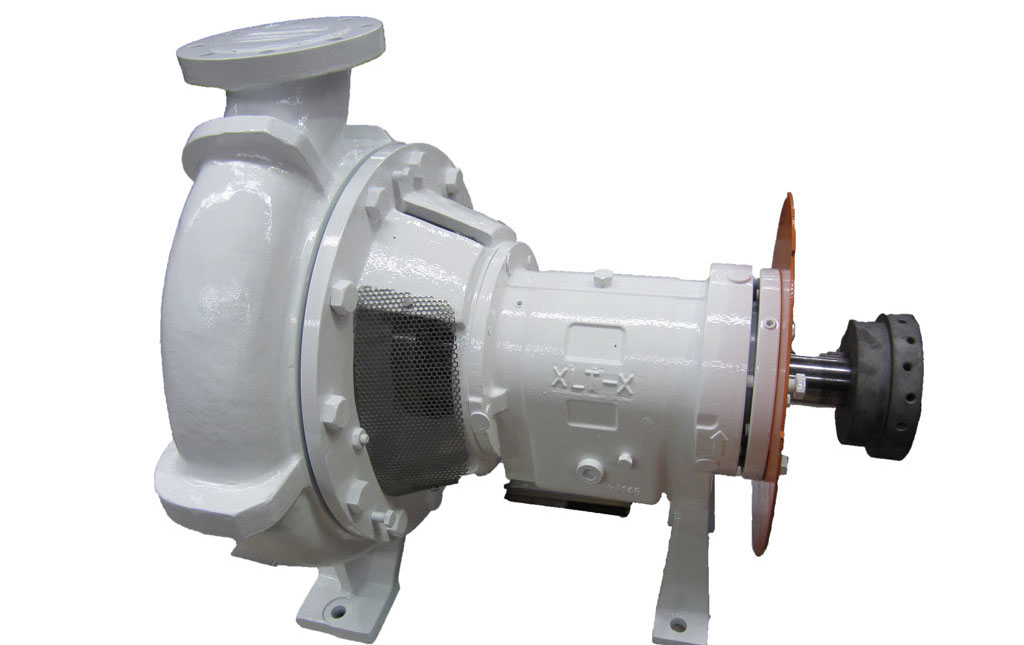

Process Pumps

Process pumps conform to particular standards as designated by the application process requirements. They are generally all widely available in exotic materials such as Hastelloys, duplex stainless steels, complex alloys & engineered plastics.

They also allow the ease of fitting a specialised range of sealing arrangements equal to the extreme requirements of the pump & generally have heavy duty drive ends to withstand the extra loads they are often exposed to.

A leading example is the API610 standard for Hydrocarbon processing plants and refineries where leakage safeguards & increased MTBF’s are necessary

Advantages

International standards to suit application specific environments

Universal glands to accept specific duty cartridge seals

Available in many engineered materials

Larger Heavy duty bearing frames

Greater performance envelope per pump & more tolerant of operation outside of BEP

Adapts more easily to varying chemical & petrochemical liquids

Wear clearances can be adjusted externally without the need to strip the pump

Limitations

Considerably more expensive than standard end suction pumps

Longer delivery lead times in Australia due to stocking cost limitations

Sealing design is complicated and expensive when using in elevated temperatures, high & low pH fluids, abrasive liquids, & high pressures.

Common brands serviced include;

Goulds, Flowserve, Durco, Summit, Egger, Hisco, Rotech, Sulzer, Griswold, Robuschi, Springer, Kirloskar, Ruhrpumpen, KSB, Phoenix